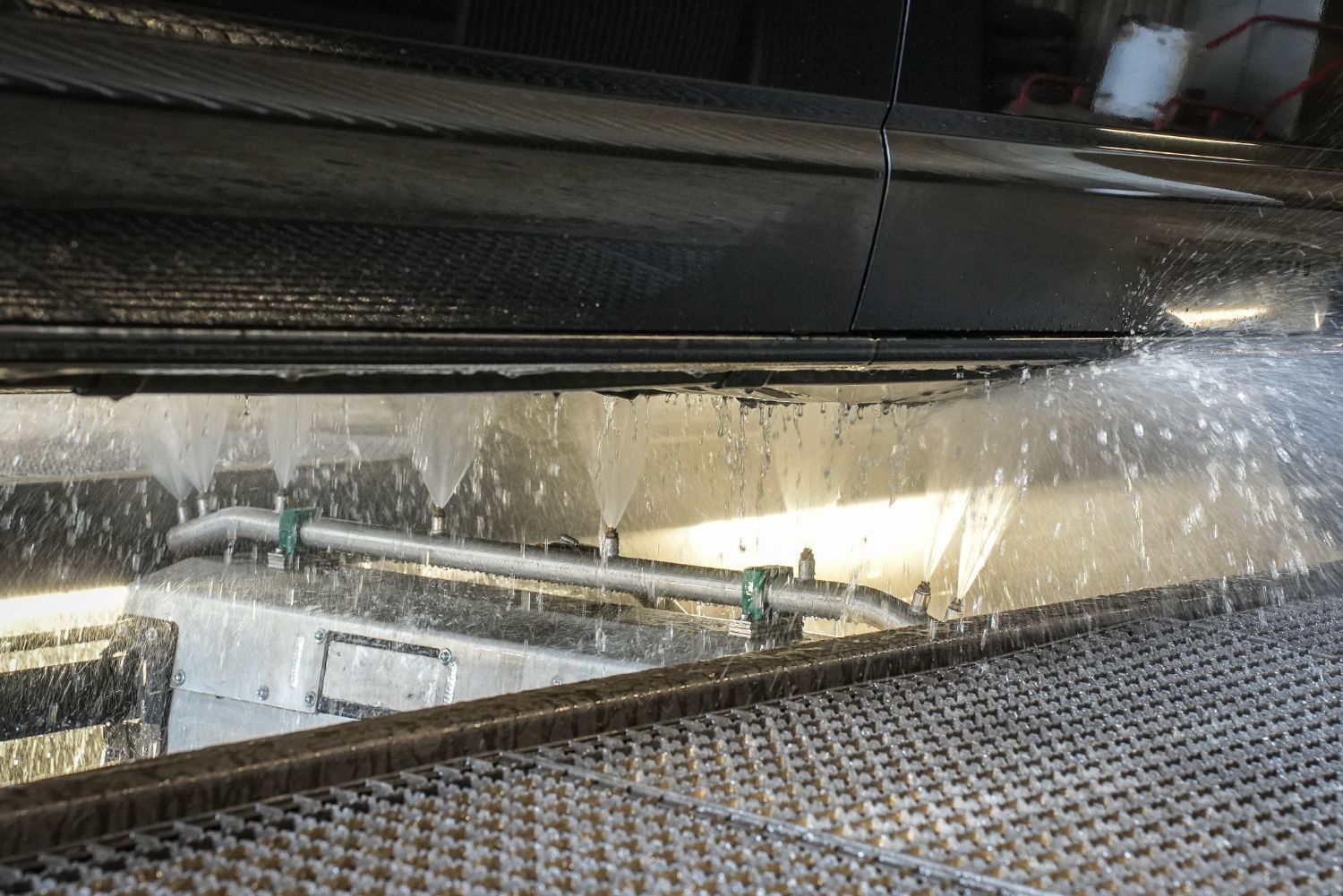

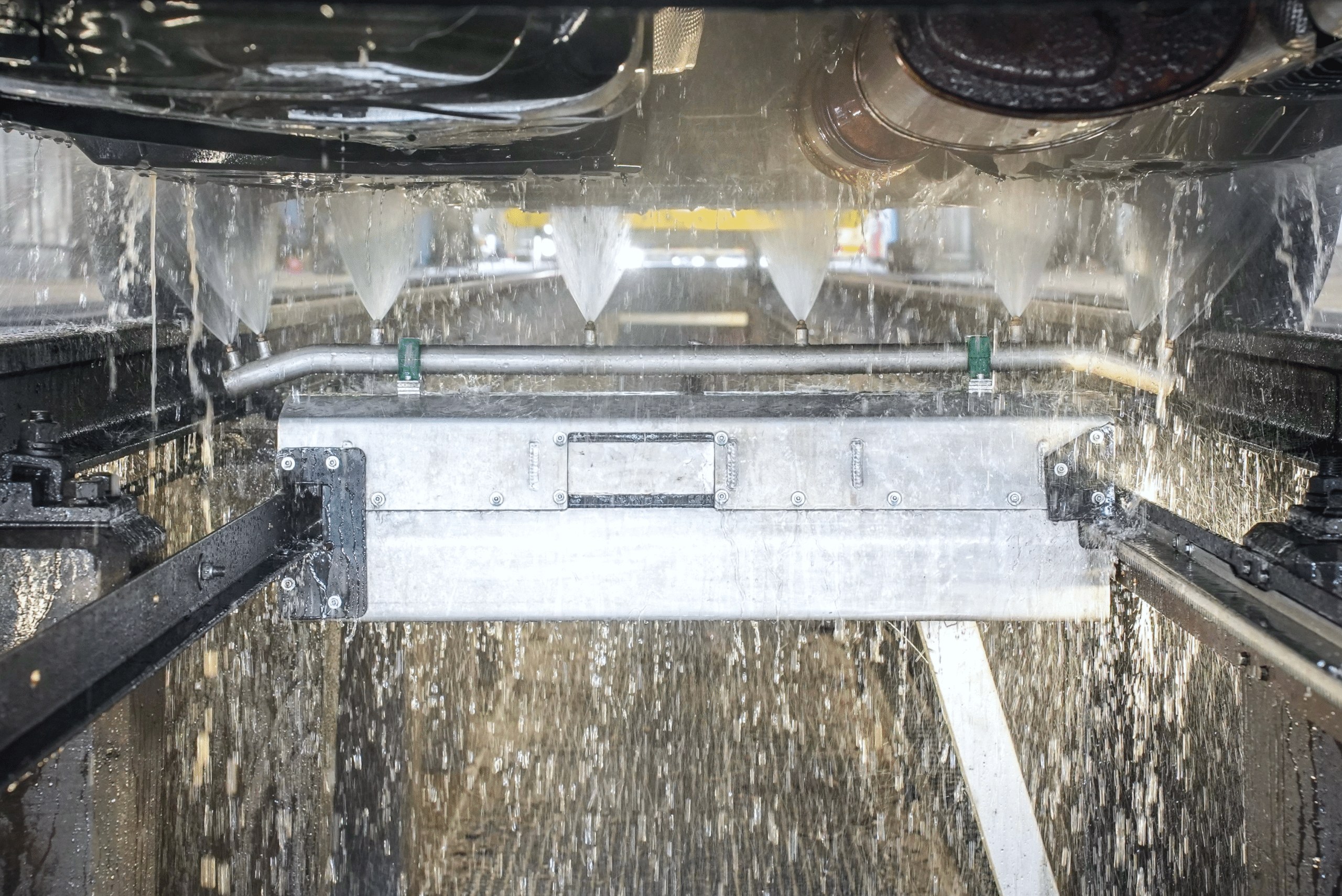

ACS – Automatic Chassis System

Freezing, soiling, and salt accumulation on vehicle underbodies are everyday challenges, especially in the logistics and maintenance sectors. These issues lead to corrosion, shorten the lifespan of equipment, and increase maintenance costs.

MOS Engineering’s fully automated underbody washing system is an effective solution to this challenge.

Melts ice, removes dirt and protects

The system melts ice, removes dirt, and rinses away salt quickly and efficiently – fully automatically, without any manual pre-cleaning. It improves equipment condition, extends its lifespan, and frees up employees for other valuable tasks.

An efficient and safe solution

Cost efficient

No need for manual defrosting before washing. Extends equipment lifespan and reduces maintenance costs.

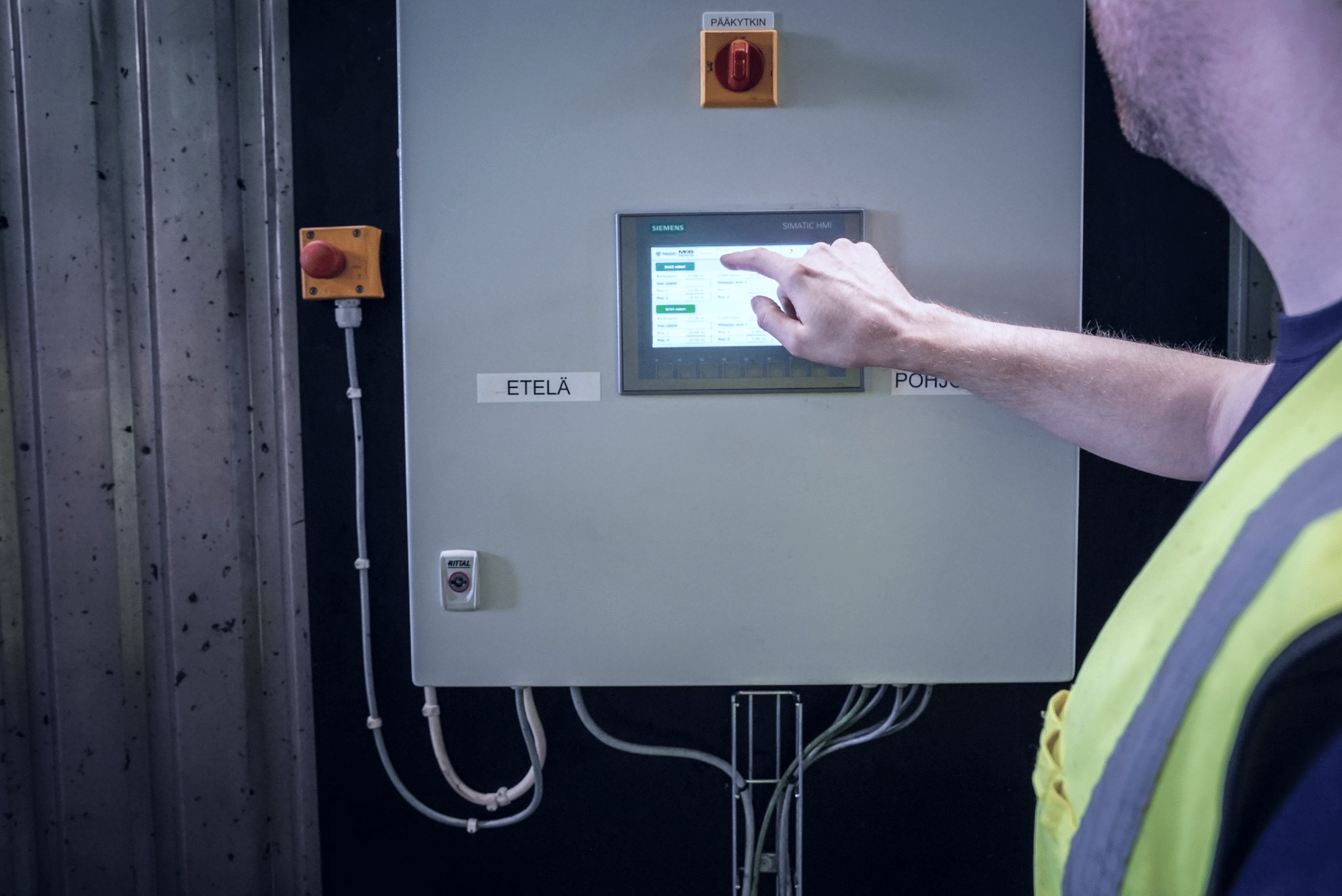

Automatic

Operates without constant supervision, freeing up time for other tasks. Also available when unexpected cleaning is needed.

Fast

An automated washing process shortens defrosting and cleaning time, keeping equipment ready for service sooner.

Safe

Usage and Features

The device is designed for indoor use and utilizes the building’s own water supply, heat and pressure. Defrosting and washing occur automatically, and if needed a detergent system can be connected to the device to enhance the cleaning results.

-

Operating speeds: Optimizable for washing situations – fast mode (3.42 m/min) or slow mode (1.38 m/min) for particularly dirty areas.

-

Defrosting speed: For example, a surface 10 meters long with a 50 mm thick layer of ice melts in about an hour (water temperature 50 °C, flow rate 60 l/min).

Would you like to learn more about the solution?